- Home

- company

- Quality Control

Strict Quality Control System

Quality is our unremitting pursuit

Quality Requirements

Southchip Limited always consistently identifies, mitigates, and ultimately eliminates ongoing risks and threats. We have implemented a Quality Management System that is continuously maintained to ensure effectiveness and drive process improvements. This system adheres to the requirements of AS9120B, ISO 9001:2008, ISO 13485, ISO 28000, ESD-S20.20, and the standards set by IDEA-STD-1010-B.

As a member of ERAI,Southchip Limited has in-depth information on the global electronics supply chain. We dramatically reduce risk in the sourcing process as we tackle the challenges posed by counterfeit electronic parts.

VIEW

ISO9001:2015 is a quality management system standard formulated by the international organization for Standardization (ISO). The standard absorbs international advanced quality management concepts. We follow a strict quality management system to provide trustworthy electronic components.

VIEW

ISO 45001 is among the certifications successfully obtained by South Chip Co., Ltd. Our establishment of a robust occupational safety and health management system for our employees guarantees the delivery of our services with utmost efficiency, expedience, and unwavering commitment to excellence.

VIEW

Southchip Limited actively mitigates the environmental footprint associated with our product portfolio. Our attainment of ISO14001 certification serves as a testament to our unwavering adherence to rigorous environmental standards and our unwavering dedication to addressing environmental concerns.

VIEW

Our DUNS certification ensures unparalleled credibility, worldwide recognition, and seamless transactions. With an unwavering commitment to superior quality, reliability, and extensive industry expertise, we offer an extensive range of cutting-edge products, catering to the diverse needs of our esteemed global clientele.

IAF is an esteemed global consortium encompassing conformity evaluation and accreditation entities on a worldwide scale. This testament to our commitment ensures that the standards we diligently adhere to meticulously align with the exacting criteria set forth by no fewer than 30+ nations.

Quality Management Team

Since the establishment of our Quality Testing Department in 2013, Southchip Limited has recruited a group of professional QC practitioners to form a mature and solid QC department

Our Quality Management Representatives have the authority and responsibility to ensure the establishment, implementation, and maintenance of processes required for the Quality Management System.

To continuously evaluate the suitability of Southchip Limited's Quality System, our professional team conducts regular internal audits and reviews the Quality System through quality reports. These reports include audit results, customer feedback, process performance, product conformity, the status of preventive and corrective actions, and follow-up actions from previous management reviews, among others.

All individuals are required to undergo regular quality project training to understand the relevance and importance of their work performance and how it supports our Quality Objectives.

In-house Inspection Capabilities

Relying on the resources of the parent company, Southchip Limited has developed a comprehensive and strict set of testing standards since its founding. We also utilize the most advanced inspecting equipment and employ knowledgeable Field Application Engineers who are dedicated to vetting all component sources and products.

All components undergo inspection and verification of their provenance in Southchip Limited's Quality Testing Department. This includes tests such as 200x magnification, Solderability Test, Acetone Verification Testing, and more. Only after passing these tests are the components entered into inventory and shipped to our end-customers.

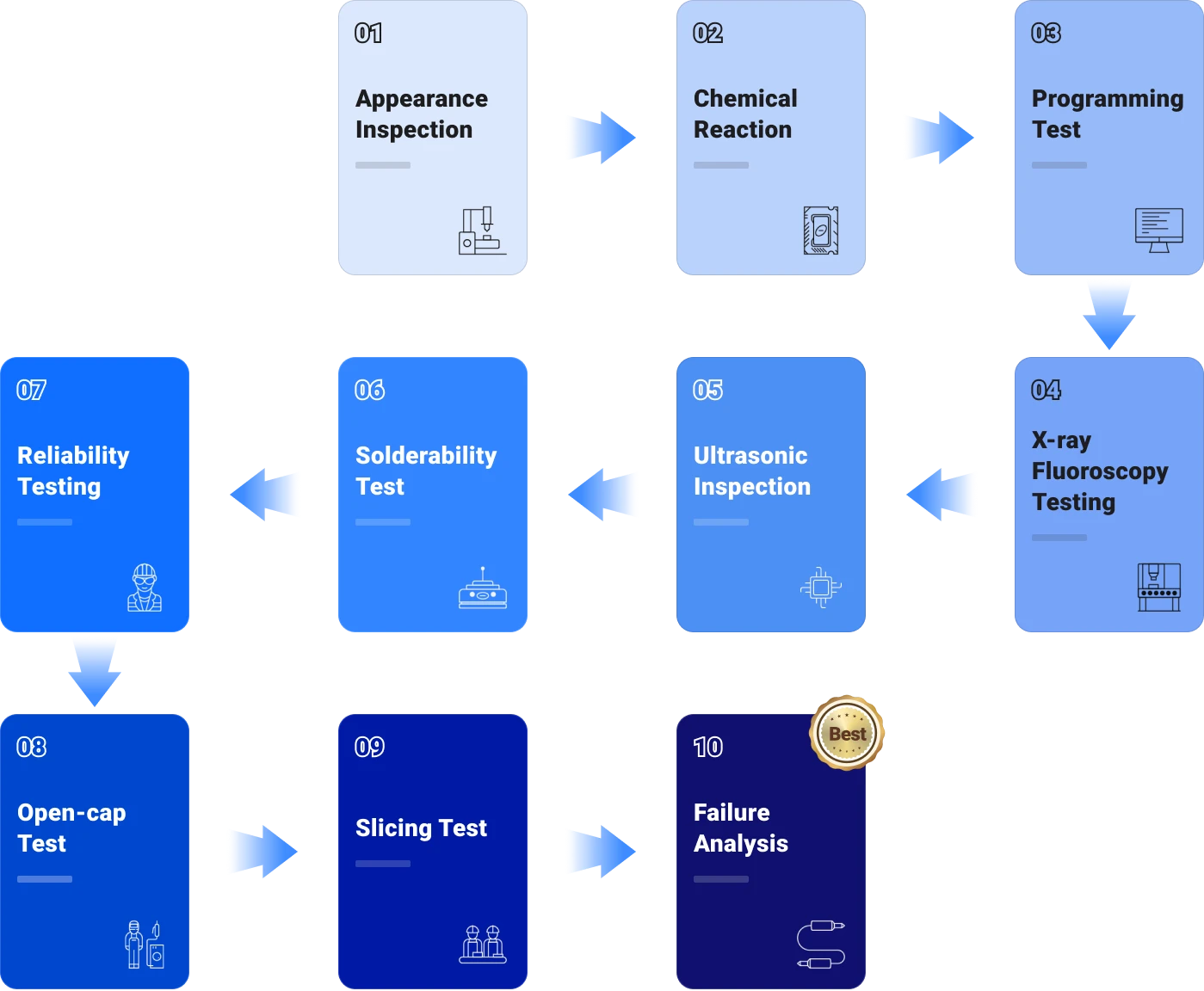

Our Quality Testing and Inspecting System

Including but not limited to Visual Inspection / JTAG Test / Thermal Shock / Tinning and Lead Conditioning Services / Acetone Verification Heated Solvents / Pb-free and RoHS Test / Solderability Test / Data sheet Verification Reliability Test / De-capsulation Test / Electrical testing / Direct Current Characteristics Test (DCCT) / Pin assignment Test / Electrical Test / Complete Visual inspection / Functional Test.

Supplier qualification control is of utmost importance as it directly affects the quality of our components. Therefore, Southchip Limited consistently implements the ISO9001:2008 management system and rigorously selects reliable supply partners. We only collaborate with high-standard distributors who meet our stringent supplier standards, including manufacturers, franchise distributors, OEMs, CMs, and independent reputable distributors. These partners form an integral part of our strict supply chain.

ISO9001:2015 is a quality management system standard formulated by the international organization for Standardization (ISO). The standard absorbs international advanced quality management concepts. We follow a strict quality management system to provide trustworthy electronic components.